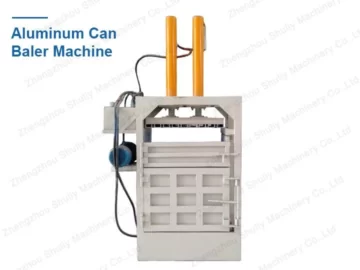

In the ever-evolving landscape of waste management, the demand for compact and versatile solutions is on the rise. Introducing the Y81-630, our small metal baler, a horizontal machine designed to efficiently bale various types of scrap metal, including paint cans, aluminum cans, metal scrap, aluminum materials, plastic bottles, steel shavings, and more. This article explores the working principles, advantages, pricing, and applications of this innovative small metal swarf baler.

Working Principles of the Small Metal Baler

The Y81-630 operates on a simple yet effective principle. When activated, the machine exerts a nominal force of 630 kN within its compression chamber (1000×600×500 mm). This force compacts the metal scraps into blocks of various shapes – rectangular, cylindrical, hexagonal, octagonal, etc. The entire process is quick, with a single cycle lasting no more than 90 seconds.

Advantages of the Small Metal Baler

The Y81-630 boasts several advantages that make it a preferred choice in the market:

- Versatility: Capable of baling a wide range of metal materials, accommodating diverse shapes and sizes.

- High Compression Density: Produces blocks with a density ranging from 180 to 250 kg/m³, ensuring efficient use of storage space.

- High Capacity: With a capacity of 500-1000 kg/h, it can handle substantial volumes of scrap metal.

- Energy Efficiency: Powered by a 7.5 kW motor, the machine operates with optimal energy consumption.

- User-Friendly Operation: The baler features a turn-over mechanism and manual valve operation for easy handling.

Pricing of the Small Metal Baler

When considering waste management solutions, cost-effectiveness is a crucial factor. The Y81-630 offers a competitive pricing structure, providing excellent value for the efficiency and versatility it brings to your metal recycling operations. For detailed pricing information, please contact our sales team.

Applications of the Small Horizontal Metal Baler

The applications of the Y81-630 small horizontal metal baler are diverse and impactful across various industries:

- Scrap Yards: Efficiently process and compact metal scraps for easy transportation and recycling.

- Manufacturing Units: Manage and recycle metal waste generated during production processes.

- Waste Management Facilities: Streamline the handling of diverse metal materials, enhancing overall efficiency.

- Environmental Initiatives: Contribute to sustainability efforts by responsibly managing and recycling metal waste.

Shuliy Baler Machinery – Your Professional Small Metal Baler Manufacturer

In the realm of small horizontal metal balers, Shuliy Baler Machinery stands out as a leading manufacturer based in China. Specializing in the production of high-quality balers, Shuliy is committed to providing efficient and reliable solutions for waste management. For inquiries about the Y81-630 or any other small metal baler models, feel free to reach out to us. We are dedicated to assisting you in finding the most suitable waste management solution for your needs.