A gantry shear is a type of industrial metal shearing machine used to shear or cut various materials, typically metal sheets, plates, waste steel, etc. It consists of a sturdy gantry framework, which serves as the support structure, and a movable cutting tool or blade that moves vertically or horizontally to perform the cutting operation.

How does a gantry shear work?

A gantry shear operates on a simple yet effective principle. The machine utilizes a sturdy gantry framework, which provides stability and support. The cutting tool, typically a sharp blade, moves either vertically or horizontally to shear the material. The blade exerts an immense force on the material, cutting through it with precision and efficiency. This mechanism ensures accurate and clean cuts, even when dealing with thick metal sheets or other materials.

Parameters of gentry waste metal shear machine

| Model | SL-800 |

| Pressure | 800T |

| Blades length size | 2m |

| Power | 380v 3phase |

| Weight | 76 Tons |

| Pushing method | hydraulic cylinder |

| Number of cuts | 3-5time/min(adjustment) |

| Size | 9000*2200*1500mm |

The above are some data parameters of the hot sale gantry shears. Besides, we also have other styles of metal shear machines for sale. If you want to know the complete machine parameters, please feel free to contact us.

What are the applications of a hydraulic gentry shearing machine?

The gantry shear finds extensive applications across various industries. Its primary use lies in metal fabrication, where it effortlessly cuts through metal sheets, plates, and profiles. You can also use it for cutting steel plate, light and thin steel, scrap copper, steel bar, nickel plate, scrap iron, steel plate, round steel, steel pipe, light metal structural parts, car body, stainless steel, metal block, aluminum alloy, copper material, metal block, scrap iron, steel wire, etc.

Additionally, it is employed in steel processing plants for precise shaping and sizing of steel components. The gentry waste metal shear machine also plays a crucial role in automotive manufacturing, shipbuilding, and construction, where the need for accurate cutting and shaping of metal is paramount.

What are the advantages of using a gantry shear?

- Exceptional Cutting Precision: The industrial metal shear machine ensures high-precision cutting, resulting in accurate shapes and sizes of the desired components.

- Increased Productivity: With its powerful cutting capabilities, the waste metal shearing machine enables faster production cycles and enhanced productivity.

- Versatility: The machine can handle various materials, including waste metal, making it a versatile choice for different industrial applications.

- Cost-efficiency: By minimizing material wastage and optimizing cutting processes, the gantry shear helps reduce costs and maximize efficiency.

The feature of the gantry shear

A notable feature of the gentry waste metal shear machine is its adaptability to different material thicknesses. It can handle a wide range of materials, including thick metal sheets and waste metal, without compromising on cutting quality. The machine is also equipped with safety measures, such as emergency stop buttons and protective barriers, ensuring a secure working environment.

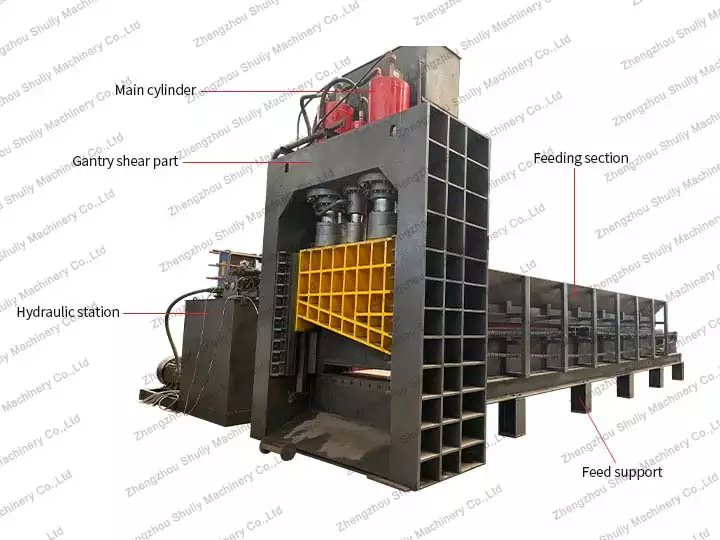

The structure of the industrial metal shear

The gantry shear consists of a robust gantry framework, which provides stability and support during the cutting process. The cutting tool, such as a blade, is mounted on a movable beam that moves vertically or horizontally. The machine may also include advanced control systems and hydraulic mechanisms to enhance cutting precision and efficiency.

How to use a gantry shear?

Using a gantry shear effectively requires proper training and adherence to safety guidelines. Operators should be familiar with the machine’s controls, such as the blade movement and cutting speed adjustments. It is essential to position the material correctly and securely before initiating the cutting process. Regular maintenance and inspection of the gantry shear are crucial to ensure its optimal performance and longevity. If you want to know detailed information about that, please contact us.

All in all, the gentry waste metal shear machine has revolutionized industrial metal cutting with its exceptional capabilities. Its versatility, precision, and efficiency make it an indispensable tool in various industries. Whether it is waste metal, thick metal sheets, or intricate profiles, the gantry hydraulic shearing machine delivers accurate and clean cuts. Do you need an efficient gantry shear to help you achieve your shearing work? If you are interested, please feel free to contact us. As a professional metal shearing machine manufacturer, we can give you a reliable suggestion.