In the competitive world of scrap recycling, efficiency is king. For recycling centers and manufacturing plants, a Vertical Metal Baler is an indispensable tool for reducing waste volume and saving on logistics costs. However, with so many models available, making the right Vertical Metal Baler selection can be overwhelming.

Should you buy a 30-ton machine or a 100-ton giant? Does the feed opening size really matter? Choosing the wrong specifications can lead to loose bales that fall apart or wasted energy bills. In this guide, we break down the two most critical factors—Tonnage (Hydraulic Pressure) and Opening Dimensions—to help you find the perfect scrap metal compactor for your business.

Understanding Tonnage: The Power Behind the Press

“Tonnage” refers to the compression force exerted by the hydraulic cylinder. It is the single most important spec when browsing metal recycling machine specs. The rule is simple: the harder and more resilient the material, the higher the hydraulic baling press pressure you need.

Here is a breakdown of how to match tonnage to your material:

Low Tonnage (20 – 50 Tons): For Light Materials

If your facility primarily handles soft, hollow, or highly deformable materials, you don’t need a monster machine.

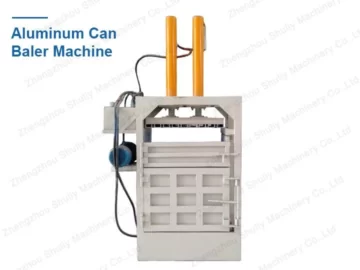

- Best for: aluminum cans (UBC), tin cans, plastic bottles, and thin aluminum scraps.

- Why: a baler for aluminum cans typically works perfectly at around 30-40 tons. The material crushes easily, and excessive pressure won’t significantly add value.

Medium Tonnage (60 – 100 Tons): For Resilient Scrap

Materials that have “memory” (a tendency to spring back after compression) require more force to ensure a high-density scrap bale.

- Best for: copper wires, stainless steel sheets, light steel offcuts, and aluminum shavings.

- Why: to keep copper wire compact, a force of 80-100 tons is ideal. This ensures the bale remains tight during transport.

High Tonnage (120 – 200 Tons): Heavy Duty Applications

For thick, tough, or bulky scrap, you need a heavy-duty vertical baler.

- Best for: car radiators, mixed ferrous metals, hard alloy scraps, and metal turnings.

- Why: only ultra-high pressure can permanently deform these structures into a solid block.

Feed Opening Size: Why It Matters for Efficiency?

While tonnage determines the quality of the bale, the scrap metal compactor feed opening determines the speed of your operation. The feed opening is the “door” through which you load the material.

Loading Efficiency:

If you are recycling large items like computer casings or car bumpers, a small opening is a nightmare. Workers will have to manually cut the scrap to fit it in, which kills productivity. Always choose a machine with an opening slightly larger than your largest common scrap piece.

Ergonomics:

For smaller vertical metal balers loaded by hand, the opening height should be ergonomic. For larger systems using a forklift or conveyor, a larger, hopper-style opening is preferred to prevent spillage.

The Relationship Between Pressure and Bale Density

Why should you care about hydraulic pressure force? Because it directly impacts your bottom line.

Shipping scrap metal is often charged by container volume, not just weight. A machine with higher tonnage produces denser bales. This means:

- More weight per container: you can fit more tons of scrap into a standard shipping container.

- Lower shipping costs: you pay less freight per ton of recycled metal.

- Better prices: smelters and refineries often pay a premium for dense, clean bales produced by a high-quality vertical metal baler.

Conclusion: Making the Right Choice

Selecting the right vertical metal baler involves balancing your budget with your performance needs.

- If you process aluminum cans, a 30-ton baler is cost-effective.

- If you handle heavy industrial waste, investing in a 150-ton heavy-duty vertical baler will pay off in shipping savings.

Still Unsure About the Specs?

At Shuliy, we specialize in manufacturing high-performance recycling equipment. Contact Us Today!

Let us know what material you are pressing, and our engineers will calculate the exact Vertical Metal Baler Tonnage and Opening Size you need to maximize your profits!