Investing in recycling equipment is a major decision. For scrap yards and metal processing plants, a Scrap metal baling press is the engine that drives revenue. It turns loose, voluminous waste into compact, valuable commodities.

But when you look at the catalog, the options can be overwhelming. 100 tons or 300 tons? Side push or forward out?

If you are asking, “How to Choose a Suitable Metal Baler?”, you are in the right place. The “best” machine isn’t necessarily the most expensive one; it’s the one that fits your specific material and production goals. In this guide, we analyze the three critical pillars of selection: Tonnage, Bale Size, and Equipment Performance.

Match Tonnage to Your Material

The first specification you will see is “Tonnage” (e.g., 125T, 250T, 400T). This refers to the Hydraulic baler tonnage or the pressing force.

Don’t just guess. The required pressure depends entirely on the thickness and elasticity of your scrap metal.

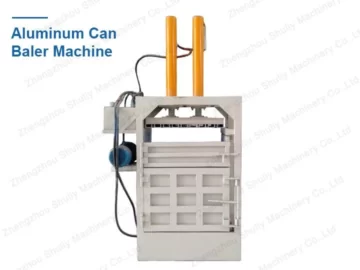

Light and Thin Material (Aluminum Cans, Tin Plate):

- Recommendation: 63 Tons – 125 Tons.

- Why: these materials are soft and have little “spring-back.” A basic Aluminum vs Steel baling machine with lower pressure is sufficient to create a tight brick. Over-investing in high tonnage here is a waste of money.

Medium Material (Copper Wire, Light Steel Structures, Stainless Steel):

- Recommendation: 160 Tons – 250 Tons.

- Why: these metals are tougher. You need moderate force to ensure the bale holds its shape during transport.

Heavy Material (Car Bodies, Scrap Steel, Rebar):

- Recommendation: 315 Tons – 600+ Tons.

- Why: for a heavy-duty scrap metal baler, you need an immense force to permanently deform thick steel. If the pressure is too low, the bale will be loose or fall apart.

Bale Size: Fit Your Furnace

The output size matters just as much as the input. When selecting a machine, consider the Bale size customization options.

The Furnace Factor:

Where are your bales going? If you are sending them to a local foundry with a small smelting furnace, you must ensure the bale dimensions (Width x Height) fit through the furnace door.

The Logistics Factor:

If you are exporting, you need bales optimized for container loading. A Metal compactor machine that produces standard-sized bales helps you maximize weight per container, reducing shipping costs significantly.

Performance and Cooling Systems

A machine might look good on paper, but how does it perform under 24/7 stress?

Cooling System:

Hydraulic systems generate heat. If you run the machine continuously for 8 hours, the oil temperature will rise, potentially damaging seals.

Solution: for high-frequency use, ensure your machine is equipped with a Water Cooler or an industrial Air Cooler.

Cycle Time:

How fast can it cycle? A machine with a “Differential Valve” system allows for rapid approach speeds and slow, powerful compression speeds. This significantly increases your hourly output.

Why Choose Our Scrap Metal Baling Press?

We understand that every scrap yard is different. That is why we don’t just sell standard models; we provide customized metal baler solutions.

High-Density Compression:

Our machines use premium hydraulic cylinders that deliver true-rated tonnage, ensuring your bales are dense and fetch the best market price.

Durability Guarantee:

We use Hardox wear plates inside the chamber. This abrasion-resistant steel ensures the machine can handle rough scrap for years without wearing out.

Smart Operation:

Equipped with PLC automatic control, our balers reduce reliance on manual labor, making your operation safer and more efficient.

Conclusion

Answering “How to Choose a Suitable Metal Baler?” comes down to knowing your material and your buyers. By matching the right tonnage and bale size to your needs, you turn waste into profit efficiently.

Still not sure which model is right for you?

Let our engineers help. Send us a photo of your scrap material, and we will recommend the perfect machine configuration.