Shuliy hydraulic alligator shearing machine, also known as an alligator shear or crocodile shear, is a mechanical device used for cutting or shearing metal materials. It is specifically designed to cut through various types of scrap metal, such as steel, iron, copper, and aluminum.

The advantages of Taizy hydraulic metal shears

- Firstly, its hydraulic power ensures high cutting force, making it suitable for cutting thick and robust metal pieces. The model SL-1200 has a cutting pressure of up to 120 tons.

- The blade length of this metal shearing machine is 400mm, 600mm, 700mm, 800mm, 1000mm, 1200mm, and other specifications for customers to choose from.

- Secondly, the crocodile mouth shear design allows for quick and efficient operation, enhancing productivity.

- Moreover, the hydraulic alligator shearing machine is easy to maintain, ensuring long-term reliability and cost-effectiveness.

Parameters of hydraulic metal shears

| Model | SL-1200 |

| Blade working width | 1200mm |

| Cutting pressure | 250 tons |

| Power | 22kw |

| Oil pump | “80*1 |

| Number of cuts | 8-12 times/mim |

| Voltage | 380V/3PH,50Hz |

| Weight | 4100kg |

| Operate type | Manual |

The blade working width of SL-1200 is 1200mm. The number of cuts per minute is 8-12. Weight is 4100kg. The above are just the parameters of one of our machines. Besides, we have other models for customers to choose. If you are looking for a high-quality alligator shearing machine, please feel free to contact us.

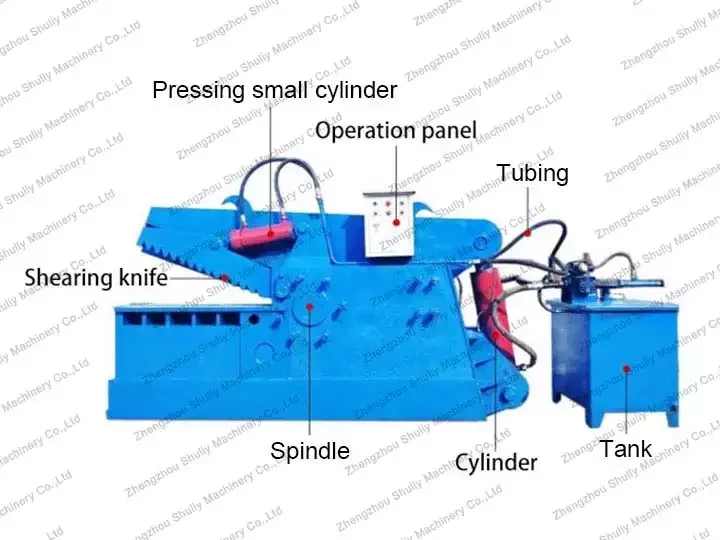

How does a hydraulic alligator shearing machine work?

The hydraulic alligator shearing machine employs hydraulic power to exert immense force on the metal being cut. Its robust design incorporates a hinged shear blade that resembles the jaws of an alligator, hence the name.

When activated, the hydraulic system drives the shear blade, clamping down on the material and delivering a clean, precise cut. The hydraulic mechanism ensures consistent pressure, enabling efficient cutting of various metal types and sizes. Users only need to adjust the size they want to cut.

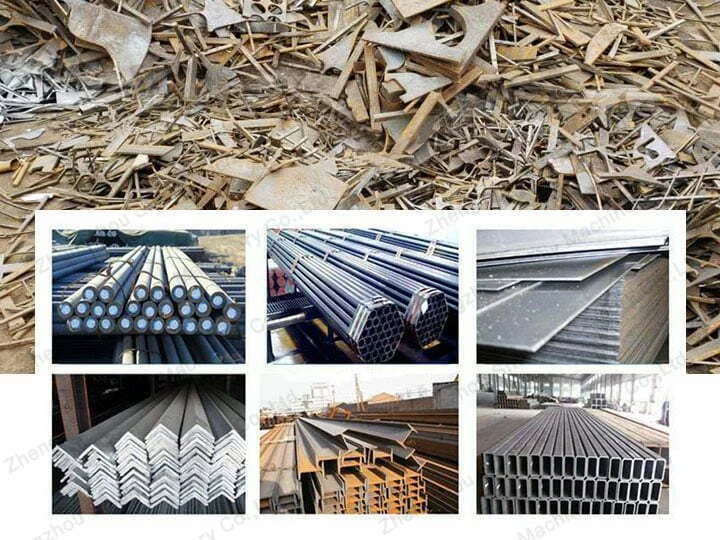

Application range of hydraulic alligator shearing machine

The hydraulic metal shears find extensive application in scrap yards, metal recycling facilities, and metal processing plants. It excels at cutting and processing scrap metal such as steel, iron, copper, and aluminum. This versatile machine tackles tasks like dismantling metal structures, cutting thick metal bars, pipes, and rods, and preparing materials for recycling or further processing.

What materials can a hydraulic alligator shearing machine cut?

The hydraulic alligator shearing machine is specifically designed for cutting a wide range of metal materials. It effortlessly cuts through steel, iron, copper, aluminum, and other non-ferrous metals. Its robust construction and hydraulic power allow it to handle even the toughest metal alloys with ease.

Hydraulic metal shears are commonly found in scrapyards, recycling centers, metal processing plants, and industries involved in metal recycling and waste management.

What are the safety precautions when operating a hydraulic alligator shear?

When operating a hydraulic alligator shearing machine, safety precautions must be strictly followed. Operators should wear appropriate protective gear, including safety glasses, gloves, and steel-toed boots. Adequate training on machine operation, emergency shutdown procedures, and safe handling of materials is essential. Regular inspection of the machine’s components and adherence to safety guidelines are crucial for accident prevention.

What are the maintenance requirements for an alligator shearing machine?

Proper maintenance ensures optimal performance and prolongs the lifespan of an alligator shearing machine. Regular inspection of hydraulic systems, lubrication of moving parts, and cleaning of debris are essential. Hydraulic fluid levels should be monitored, and filters should be replaced as recommended by the manufacturer. It is advisable to schedule routine maintenance checks by qualified technicians to address any potential issues and ensure smooth operation.

Alternative machines for cutting metal

While the hydraulic alligator shearing machine is highly effective for metal cutting, there are alternative machines and tools available for specific cutting requirements. Some commonly used alternatives include:

- Guillotine Shears: Guillotine shears utilize a downward cutting motion to slice through metal sheets and plates. They are particularly suitable for straight cuts and large-scale industrial applications.

- Bandsaws: Bandsaws employ a continuous loop of toothed blades to cut through metal. They are versatile and capable of making curved or intricate cuts in various materials.

- Plasma Cutters: Plasma cutters utilize a high-velocity jet of ionized gas to melt and remove metal. They are ideal for cutting thick metals and are commonly used in fabrication shops and industrial settings.

- Laser Cutters: Laser cutters use a high-powered laser beam to precisely cut through metal. They offer high accuracy and are favored for intricate designs and fine details.

- Oxy-Fuel Cutting: Oxy-fuel cutting involves the use of fuel gas and oxygen to create a high-temperature flame, which melts and removes the metal. This method is commonly used for thick steel cutting.

- In addition, we also have gantry scissors and tiger-head scissors for customers to choose from.

It is important to consider the specific cutting requirements, material thickness, and desired precision when selecting the most appropriate cutting tool or machine. Each alternative method has its advantages and limitations, and the choice depends on factors such as cost, efficiency, and the desired end result.

Summary

The hydraulic alligator shearing machine, a type of hydraulic metal shear, offers efficient and precise metal cutting capabilities. Its versatility makes it indispensable in the scrap metal recycling industry, where it handles a wide range of materials and prepares them for further processing. If you need this machine, please feel free to contact us. We will contact you ASAP.