In today’s recycling market, small and medium-sized scrap yards face a tough reality — low scrap density, high transport costs, and storage limitations. Every ton of loose scrap takes up valuable space and sells for less.

That’s why more recyclers are switching to metal briquette machines — compact and efficient solutions that turn loose metal chips into dense, high-value briquettes.

What Is a Metal Briquette Machine?

A metal briquette machine compresses loose metal chips, turnings, or powders into solid, cylindrical briquettes under high pressure.

The machine uses a hydraulic system to squeeze materials like aluminum, steel, copper, iron, or brass without any binders — resulting in clean, reusable briquettes that are easy to handle, transport, and smelt.

How Does a Metal Briquette Machine Work?

- Feeding: scrap metal shavings, chips, or powder are fed into the hopper.

- Compression: a hydraulic piston applies high pressure, forming dense briquettes.

- Automatic discharge: the finished briquettes are ejected automatically and collected for storage or sale.

- Recycling and reuse: briquettes can be directly remelted in furnaces, improving metal recovery rates by up to 95%.

This process reduces waste volume by up to 80%, cuts handling costs, and boosts your plant’s environmental efficiency.

Advantages of Using a Metal Briquette Machine

Maximize Metal Value

By compressing light and oily metal chips into solid briquettes, recyclers can increase resale prices by 20–30%.

Save Space and Transportation Costs

The briquettes are dense and uniform, reducing storage space requirements and freight costs.

Cleaner and Greener Recycling

Our machine removes cutting oil and coolant during compression, allowing you to recycle both metal and oil — a win for both profits and sustainability.

Low Maintenance, High Reliability

Equipped with industrial-grade hydraulic systems and a fully enclosed structure, the machine ensures stable performance and minimal downtime.

Fast ROI

Many clients in Indonesia and Eastern Europe report a payback period of less than one year, thanks to higher material utilization and lower labor needs.

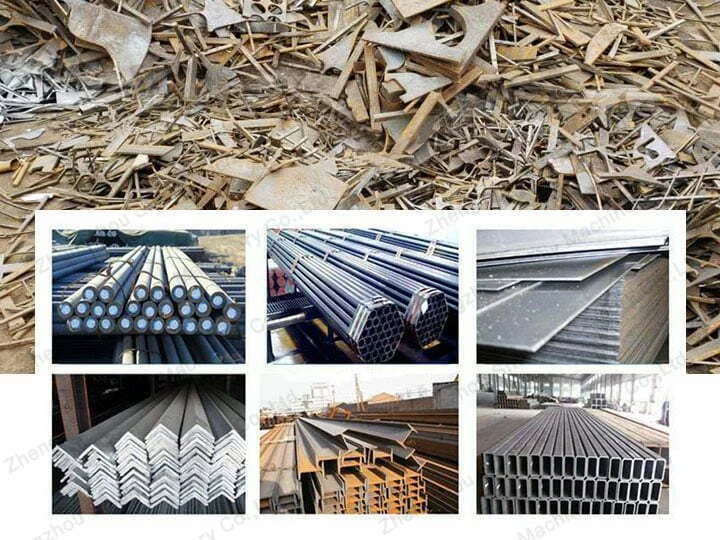

Applications Across Recycling Industries

The metal briquette machine is widely used in:

- Metal recycling plants

- Machining workshops

- Steel mills

- Foundries and smelting plants

- Automotive parts manufacturers

It is compatible with aluminum chips, iron filings, copper dust, steel shavings, and more, making it a versatile choice for any metal recovery business.

Why Choose Our Metal Briquette Machine?

Our factory specializes in custom-built hydraulic briquetting machines designed for continuous, heavy-duty operation.

Each unit is manufactured with:

- Wear-resistant alloy steel molds

- Energy-efficient hydraulic pumps

- Smart PLC control panels

- Custom briquette sizes (60–130 mm diameter)

We provide turnkey recycling solutions, integrating shredders, conveyors, and briquette presses for a complete metal recycling line. This ensures higher throughput, better briquette density, and longer machine lifespan.

A Smart Investment for Every Scrap Recycler

If you are running a metal recycling plant or machining workshop, investing in a metal briquette machine is one of the smartest and fastest-paying decisions you can make.

It not only helps you manage scrap more efficiently but also turns waste into profit, reduces pollution, and strengthens your competitiveness in the global recycling market.